What is a Single-Use Component?

Learn how single-use components are used through a variety of applications, and provide an efficient solution to many areas of a bioprocess.

What is a Single-Use Component?

Single-Use Components are disposable solutions that serve a variety of uses in bioprocessing, including maintaining the physical integrity of a bioprocess or helping to ensure a system, like one for aseptic processing, stays closed. They are typically made of plastic, and single-use components can include tubing, bags, connectors, bottles, filters, and much more.

Single-use components are the building blocks used to create single-use assemblies. We discuss the process of creating single-use assemblies further in our previous article, “What is a Single-Use Assembly?”.

Single-Use Components in Biopharma

In a previous article, we discussed how single-use solutions can often be the most efficient, and sometimes the most environmentally friendly option. Like single-use assemblies, single-use components reduce downtime by removing the need for cleaning and sterilization between batches, and can reduce the environmental impacts of the harsh cleaning solutions used on multi-use alternatives.

For these reasons, many organizations in biopharma, especially those who have customers who rely on quick drug discovery and production for treatments that save lives, choose to use single-use components across their processes.

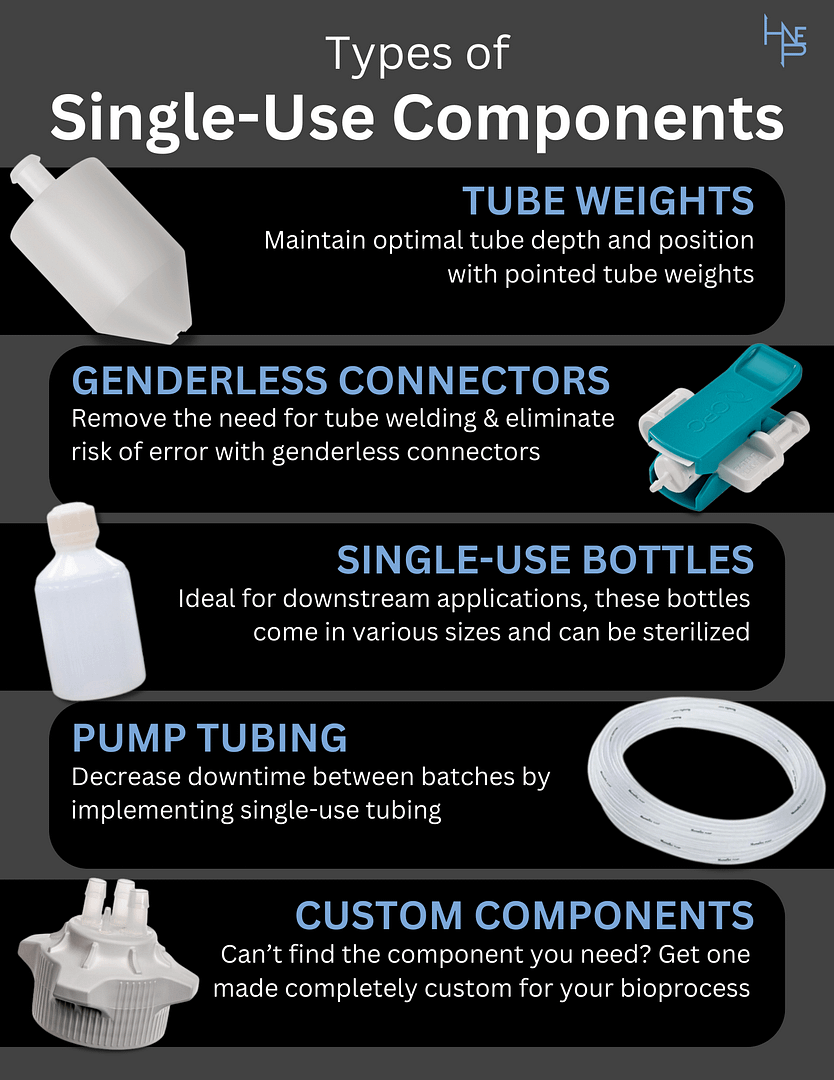

Types of Single-Use Components

High Purity New England (HPNE), a leading supplier of biopharmaceutical solutions, carries a wide range of single-use components. They have thousands of components in their component library, allowing them to create any assembly design to meet your bioprocess needs.

To create closed systems without needing to worry about tube welding, their AseptiQuik and MicroCNX™ Connectors from Colder can connect your tubing in a simple, three-step process.

Their Biosinker Tube Weights were created to maintain optimal depth and placement of your tubing. In order to ensure your tube weights can reach every area of your bottle without floating, curling, or sticking, Biosinker is designed with a unique pointed tip. For tubing, HPNE carries Pump Tubing from Masterflex, which is available in a range of sizes and optimized for accurate performance and durability.

For downstream applications including bulk drug substance storage and cell therapy applications, their Purillex Single-Use Bottles from Savillex are the ideal solution, and have a range of sizes from 50mL to 2000mL. They are highly transparent and manufactured from the highest purity grades of FEP resin, gamma sterilized ETFE, and virgin PFA.

Sometimes, your process calls for a single-use component that is not available to your exact specifications in the market. In that case, it is possible to get your single-use components custom made. HPNE offers Custom Fabricated Bioprocess Components, which aim to help you eliminate bioprocessing challenges, create solutions to unique problems, and ultimately create virtually any component you could need. To learn more, reach out to info@hp-ne.com.

Gendered vs. Genderless Designs

You may encounter the terms gender and genderless when researching single-use components, especially connectors. In a typical connection, a female connector would need to be paired with a distinctly different male connector to make a full connection. However, genderless designs eliminate the chance that the connectors you are using are not compatible.

Additionally, the other advantages to using a genderless connector are reduction in inventory, simplicity in scaling up connections, reduction in operator error, and minimized risk of ordering the incorrect connectors. Learn more by exploring options from Colder, who are leading the industry in genderless connector designs.

Single-Use Component Fittings

Single-use components like connectors and valves can have a variety of specific fittings, which can play a vital role in their involvement in a tubing assembly. Tubing fittings alter the direction of flow, as well as the number of points from which fluid flows in and out of the connection. For example, a Y fitting could have fluid enter the connector from one tube, then split from that point into two separate tubes.

Additional fitting types can include cross, elbow, tee, straight, multi-port, and many more. When deciding which component fitting to go for, it is important to determine your desired flow path for optimal results.

Looking for Single-Use Components for Your Bioprocess?

HPNE has a team of experts that are ready to match you with the best single-use component solution for your specific needs. Reach out to a member of their team to get started and find the perfect fit for your application needs.

Share article

About HPNE

As the industry needs grow, High Purity New England, Inc. continues to supply the biopharmaceutical industry with a range of innovative products, from drug discovery and development to fill-finish, including their flagship product, custom single-use assemblies, as well as pumps, sensors, bioreactor systems, storage and handling solutions and other single-use solutions. Along with their own manufactured products for the global market, they are also a distributor for more than 18 brands in North America.