What is Single-Use Manufacturing

Explore the benefits and Applications for Single-use Manufacturing

What is single-use manufacturing?

Single-use manufacturing is the production of a finished product that is designed to be used once. In the biopharmaceutical industry, single-use manufacturing is an important and growing part of the industry.

Why utilize single-use manufacturing?

There are many advantages to single-use manufacturing in the biotech and biopharmaceutical industry. As the industry continues to grow, evolve and change, the processes used for their development are continuously updated. With each new R&D test, there is a slight change to the fluid used, or material compatibility changes, with all these changes, solutions designed for a single-use are more effective than their multi-use counterparts.

When a solution is manufactured for a one time use, it is designed for one application, allowing it to be tailored to the exact needs of said application. This leads to optimal performance for the desired bioprocess and could be the difference between a successful or failed trial.

When a project comes to an end, you can throw away the old assembly and begin setting up the new process. With products built for multi-use, the products have to be disassembled, cleaned extensively with chemicals to ensure no contamination passes from one application to the next, and repurposed into the new bioprocess. Between the time to clean the products and the cost of chemicals, the single-use option becomes more advantageous for big pharma companies.

Cut Down Change-Out Times

Benefits to Single-use Manufacturing

Single-use assemblies are created to your exact needs for a specific process. When purchasing multi-use equipment in comparison, you have to make sure the piece of equipment will work across multiple applications, sometimes sacrificing unique features of each individual application. Choosing to use single-use manufacturing means that your assemblies will be a perfect fit every time, even if you are changing their applications monthly, weekly, or even daily.

When cleaning multi-use equipment, there is always a small chance that trace particles of the substance you are working with could be left behind in trace amounts due to human error or another mistake. By using single-use assemblies, you remove the risk that your next batch may be contaminated by the previous with single-use assemblies, which are typically constructed in a sterile environment and come in cleanroom ready packaging.

Despite being single-use, the disposable products are more eco-friendly as their disposal avoids the use of environmentally harmful chemicals used in the cleaning of multi-use solutions.

Reduce Contamination Risks

Greater Flexibility

Single-use Solutions

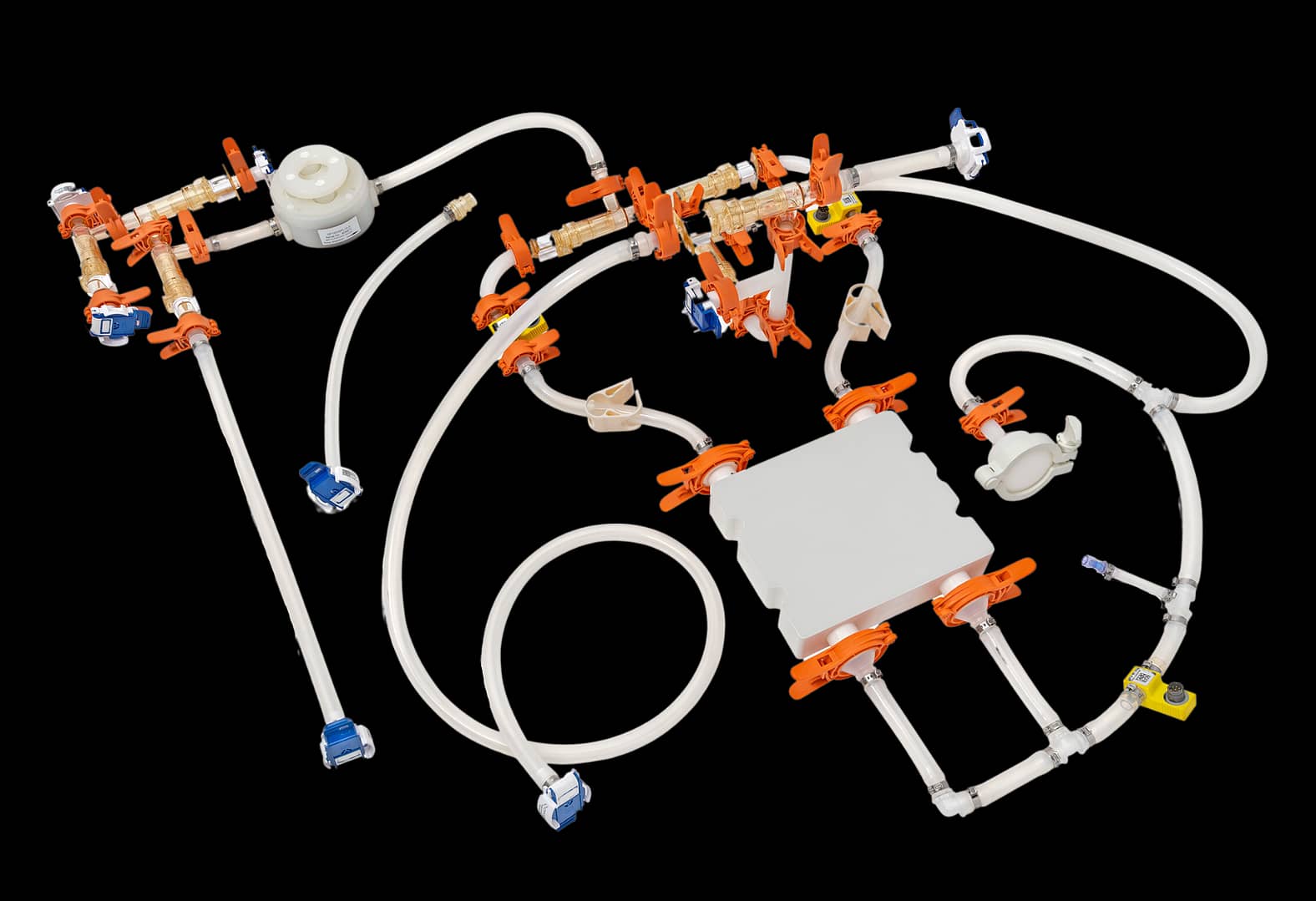

High Purity New England offers a wide range of single-use solutions to the biopharmaceutical industry. HPConnexx™, their single-use assembly solution is designed for customers of all sizes with no minimum order quantity. It also provides complete customization to ensure the perfect solution for your application. HPNE also offers a wide range of single-use sensors in order to achieve the desired flow rate.

Single-Use Manufacturing at HPNE

All single-use assemblies from High Purity New England are manufactured in their ISO 7 cleanrooms. The process is started with their experienced team of single-use engineers, and would not be possible without their expert research, design, and validation services teams. HPConnexx™ assemblies manufactured at HPNE have a high degree of customizability, as components used in their assemblies are brand agnostic.

All employees entering the cleanrooms at HPNE follow a thorough gowning procedure to make sure all sanitation requirements are met. Examples of applications for HPConnexx™ assemblies include buffer and media prep, tangential flow filtration (tff), chromatography, and sterile filling. There are additional complementary services available at their facilities for single-use assemblies, including system integrity testing, and material compatibility testing.

Read more about single-use products like HPConnexx™ in our previous article, “What is a Single-Use Assembly?”, or learn about similar single-use products in "What is a Single-Use Component" and "Single-Use Pumps in Biopharma".

Share article

About HPNE

As the industry needs grow, High Purity New England, Inc. continues to supply the biopharmaceutical industry with a range of innovative products, from drug discovery and development to fill-finish, including their flagship product, custom single-use assemblies, as well as pumps, sensors, bioreactor systems, storage and handling solutions and other single-use solutions. Along with their own manufactured products for the global market, they are also a distributor for more than 18 brands in North America.