Stop Pushing and Pulling, Our Electric Tugs For Biopharma Are Your Solution

Upgrade Your Biopharmaceutical Handling Procedures Improve safety and productivity in your Biopharma environment – get to know our line of electric tugs! With…

Upgrade Your Biopharmaceutical Handling Procedures

Improve safety and productivity in your Biopharma environment - get to know our line of electric tugs! With 3 different sizes and 4 unique models in the stainless steel product line, these tugs are engineered to work successfully in production processes and cleanroom environments where others won’t.

Designed with ISO cleanroom standards in mind, our MasterMover electric tugs utilize a hydraulic coupling point that improves ergonomics on the production floor. With customization options available, all of our electric tugs can be operated by a single user to move your heaviest equipment such as, chromatography columns, bioprocess containers, agitators & reactors, tanks & vessels, refrigerated cabinets, and single-use equipment.

Electric tugs are proven to help increase productivity while reducing the risk of costly workplace injuries. It is never too late to evaluate safety improvements. Electric tugs in legacy operations or new operations can drastically change not only safety but efficiency and effectiveness. They can accommodate a variety of needs and a wide range of end users including,

Engineers

Single-use no longer means small volume. Utilize the entirety of your ballroom layout and move heavy equipment with ease. When it comes to lean manufacturing, eliminate waste and reduce manpower with our line of electric tugs.

EH&S Professionals

Stop operators from pushing and pulling, there is a much better way. Avoid injuries and protect valuable employees.

Facilities Managers

With it's small footprint, huge power and tight turning radius, it will make any crowded cleanroom or production space workable.

A More Tailored Handling Solution

"What happens to your suite when reconfiguring is made easy?" says Mark Sitcoske, CEO/Founder of High Purity New England. “The drive to be more flexible, driven by advanced technologies increases the need for rapid reconfiguration, increasing handling demand."

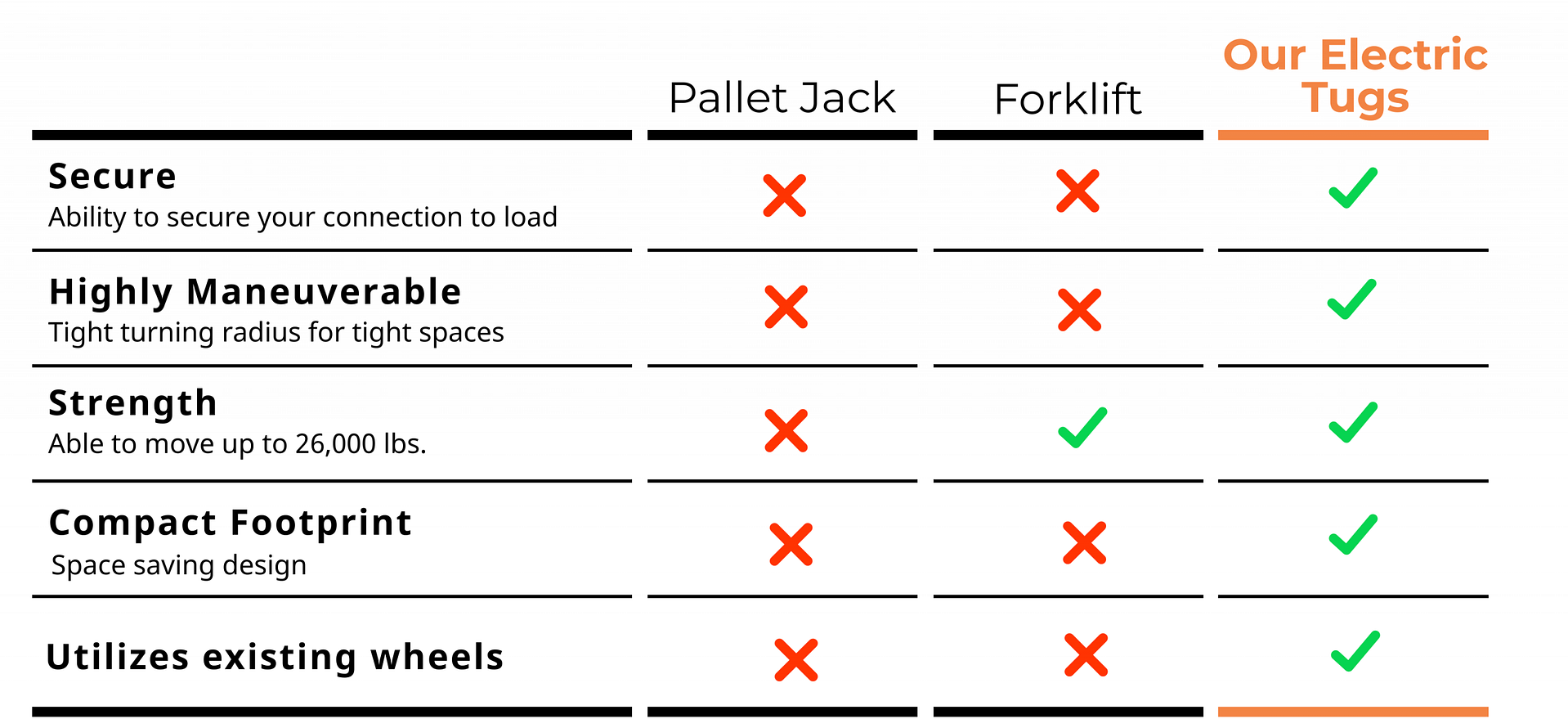

Unlike other current handling equipment that is used in biopharmaceutical cleanroom environments, our electric tugs are designed and tailored specifically for this purpose. Using weight transfer technology, a single operator can move heavy loads at slow and controlled speeds - from 100 lbs. to 26,000 lbs.

Our Complete BioPharma Range

SmartMover SM100+ SS

Our SmartMover SM100 pedestrian tug is our smallest model and allows you to avoid the risk of injuries from manual handling. Able to move up to 2,640 lbs., this electric tug design is perfect for moving mixing vessels, totes, tanks, and skids in your cleanroom facility.

MasterTug MT5/400+ SS

Made with a 316 grade stainless steel chassis, the MasterTug MT5/440+ SS is our medium range for handling solutions. With a 180 degree swivel for tight turns, this electric tug allows for incredible handling when moving 1000 liter totes, chromatography columns, and super skids.

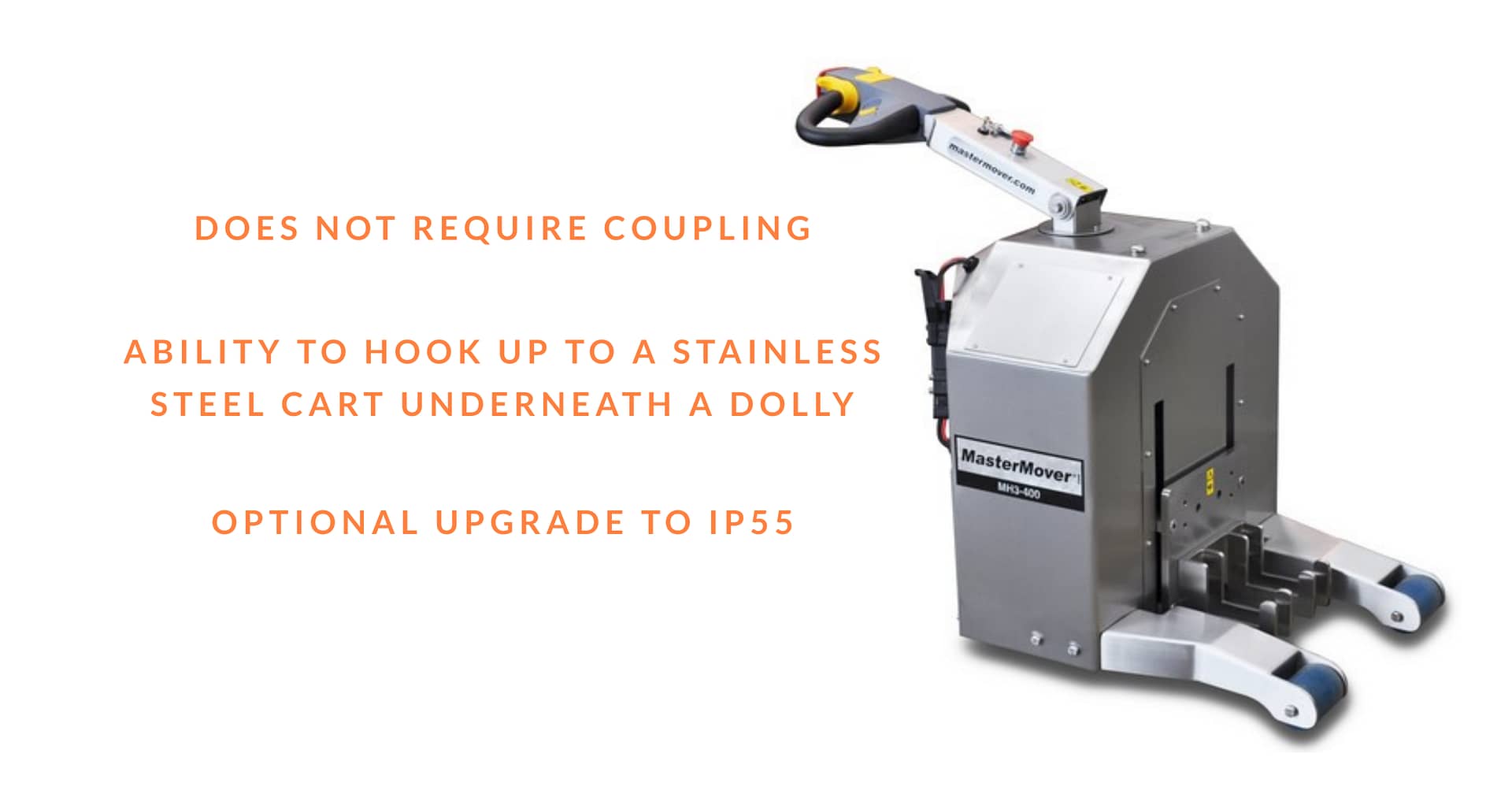

MasterHandler MH400+ SS

Ideally suited for flat terrain, the MasterHandler MH400+ electric tug offers complete control and maneuverability to make your operation mobile and flexible. The MasterHandle is the perfect alternative to our coupling options. If you are looking to move products that already have swivel mounting, the MasterHandler will make maneuvering easy.

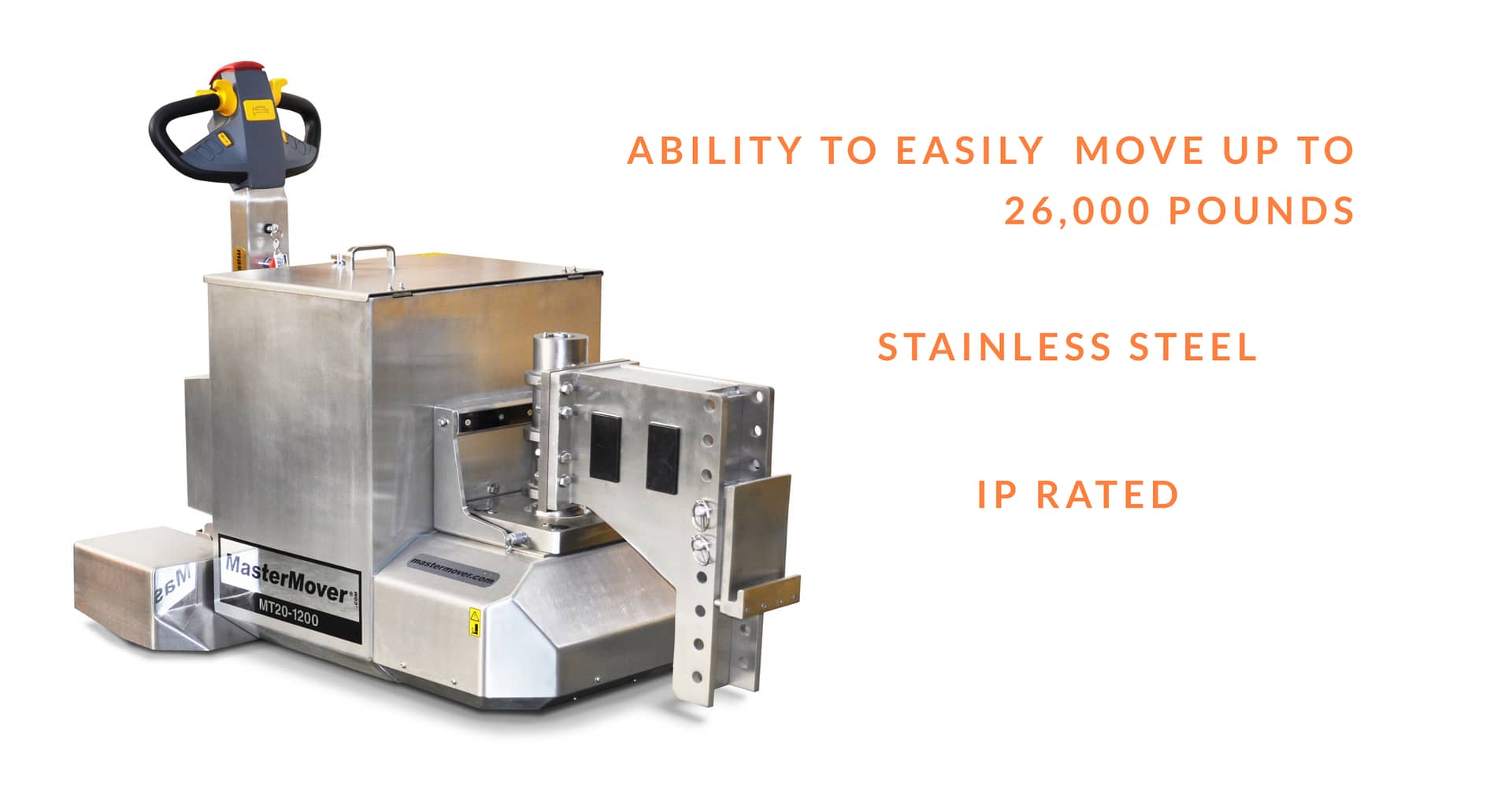

MasterTug MT20/1200+ SS

The MasterTug MT20/1200+ can handle even your heaviest equipment, making it perfect for large commercial grade production. Powerful enough to move your heaviest column yet easy to use, this electric tug features a compact size and improves safety while reducing manual handling.

Share article

About HPNE

As the industry needs grow, High Purity New England, Inc. continues to supply the biopharmaceutical industry with a range of innovative products, from drug discovery and development to fill-finish, including their flagship product, custom single-use assemblies, as well as pumps, sensors, bioreactor systems, storage and handling solutions and other single-use solutions. Along with their own manufactured products for the global market, they are also a distributor for more than 18 brands in North America.