Stainless Steel Turbine Flow Sensor

Improved Performance In Higher Pressure

Our Equflow Stainless Steel Flow Sensors feature performance in higher process pressure (optionally up to 200 Bar) and infrared (IR) turbine rotor reflection results in accurate and repeatable flow measurements.

Designed for Long Term Use

Our innovative Equflow Stainless Steel Turbine Flow Sensors can help to streamline your bioprocessing, with a flow rate of 0.06- 40L/min designed for long term use.

Overview

Our Equflow Stainless Steel Turbine Flow Sensor has low flow sensing capacities in a wide range of applications. An ultra lightweight turbine rotor follows the fluctuation of the flow very accurately and generates a high resolution infrared reflected digital output signal. With high accuracy and repeatability, this sensor is superior for measuring through revolutionary infrared turbine reflection. Featuring a high resolution output, this stainless steel sensor has outstanding performance for high process pressure.

With an accuracy rate of 1% of the reading, these stainless steel turbine flow sensors are ideal for outstanding performance in a wide range of applications.

Features & Benefits

- High chemical resistance

- Infrared (IR) turbine rotor reflection results in accurate and repeatable flow measurements

- High resolution square wave output

- Wetted parts made out of PVDF or PFA (depending on size), SS316L, ruby bearing, and FPM (Viton) sealing

- Outstanding performance in higher process pressure (up to 200 Bar)

- Sanitary Tri-Clamp process connector available

- Suitable for opaque liquids

- High accuracy and repeatability

Documents

Applications

- Diafiltration

- Tangential Flow Filtration (TFF)

- Virus Filtration

- Harvesting

- Fill and Finish

- Perfusion

- Nano Filtration

- Chromatography

- Sterile Filtration

- Research

- Process Development

- As well as many other applications

Technical Specs

| Model: 0045 | Model: 0085 | Model: 0125 | |

|---|---|---|---|

| Inner diameter in mm | 4.6 | 8.5 | 12.5 |

| Linear flow range | 0.1 – 2.0 L/min | 1.0 – 20.0 L/min | 2.5 – 40.0 L/min |

| Minimum flow | 0.03 L/min | 0.5 L/min | 1.5 L/min |

| Accuracy | 1% of reading | 1% of reading | 1% of reading |

| Repeatability | < 0.15% | < 0.15% | < 0.15% |

| Wetted parts | SS316L / PFA or PVDF / Ruby | SS316L / PFA or PVDF / Ruby | SS316L / PFA / Ruby |

| O-ring seals | Viton or EPDM | Viton or EPDM | Viton or EPDM |

| Connections | ¼” BSP/NPT | ⅜” BSP/NPT | ½” BSP/NPT |

| Dimensions incl. housing in mm | 69 | 81 | 72 |

| Liquid temperature in °C | -20 to +80 | 20 to +80 | -20 to +80 |

| Max. pressure at 20°C in bar | 100 | 100 | 100 |

| Viscosity in cSt. | 0.8 - 10 | 0.8 - 10 | 0.8 - 10 |

| Approx. K-factor in pulses/L | 100,000 | 4,800 | 2,000 |

| Power Supply | 5 - 24 Vdc | 5 - 24 Vdc | 5 - 24 Vdc |

| Output signal | 5 - 24 V square wave | 5 - 24 V square wave | 5 - 24 V square wave |

| Power consumption | 34 mA at 5 V | 34 mA at 5 V | 34 mA at 5 V |

| Default cable | PVC 1 meter | PVC 1 meter | PVC 1 meter |

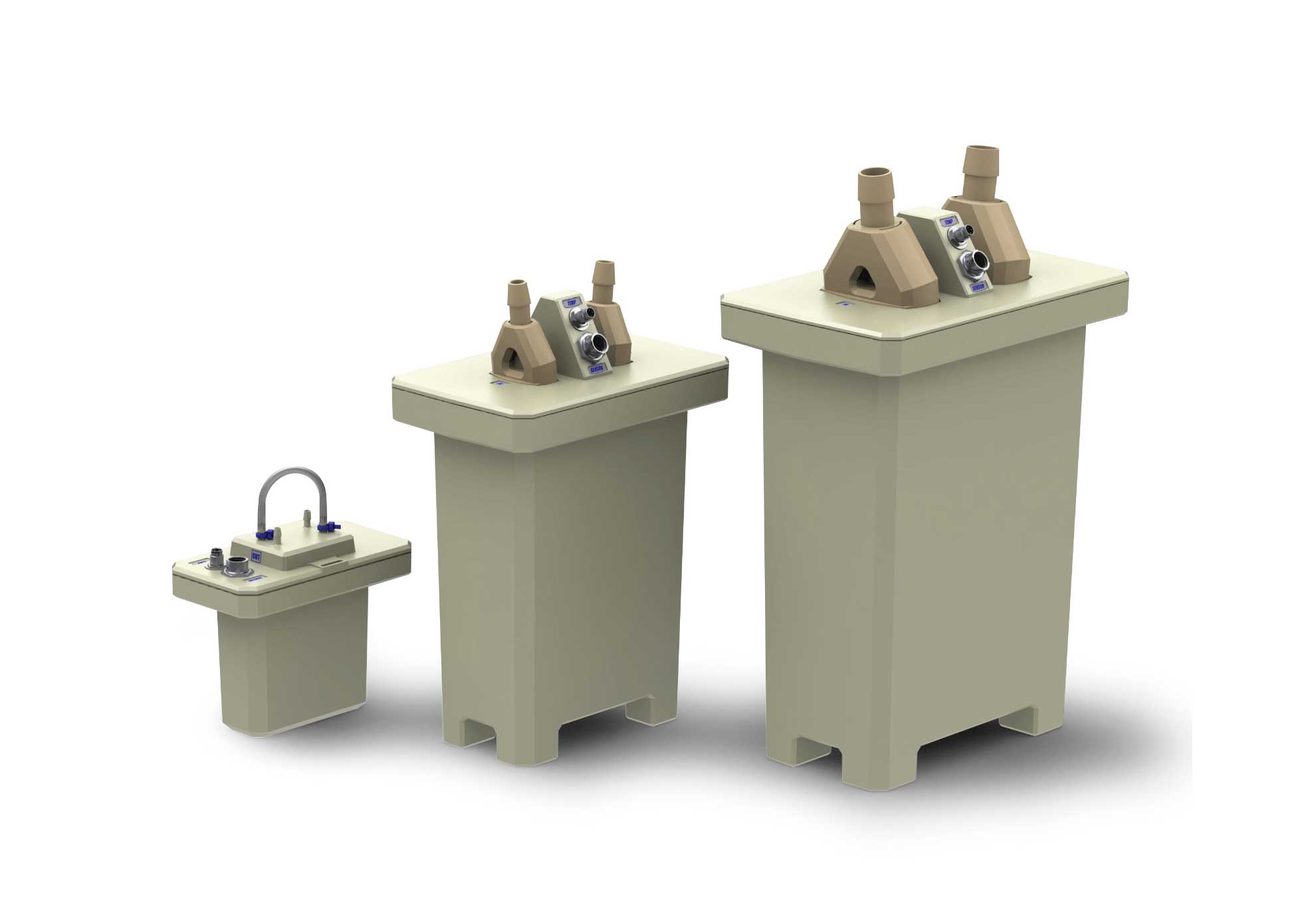

Product Comparison

Turbine

Flow Sensor

- Stainless steel flow sensor

- Flow range: 0.06 – 40 L/min

- 3 models available

- High accuracy and repeatability

- Infrared (IR) turbine rotor reflection

- Suitable for opaque liquids

Electromagnetic

Flow Sensor

- Accuracy of 1%

- Gamma/Autoclave Stable Flow Tube

- Minimal hold-up volume

- Accommodates two flow tubes

- Full bore flow path

- Factory calibrated

Mass Coriolis

Flow Sensor

- Accuracy: +/- 1% of flow

- Gamma stable PEEK sensor

- For ultra low flow

- Flow pressure of 30 psi

- Designed for measuring liquids

- Materials: Unreinforced polyether ether ketone

Non-Invasive

Flow Sensor

- Ultrasonic sensor

- Up to 7 calibration tables

- Compact size

- Waterproof design

- Up to 50C operating temp

- Customer specific calibration