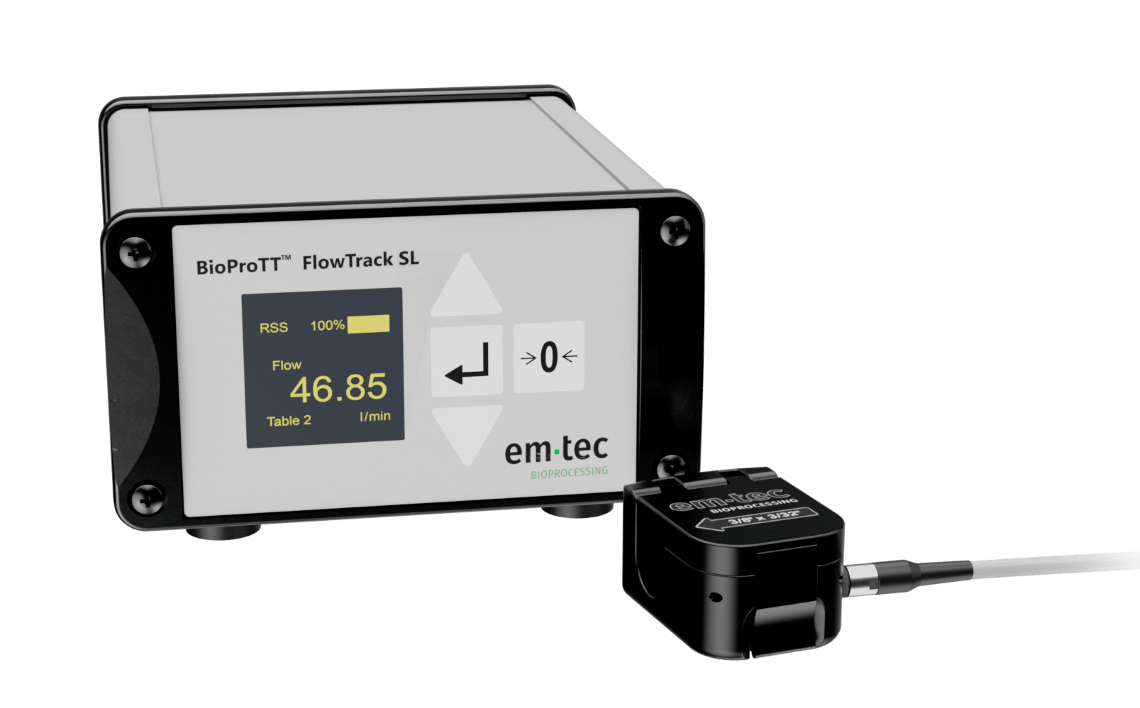

BioProTT Flowtrack SL Remote Display

Improved Process Performance

Our innovative BioProTT FlowTrack SL can help to streamline your bioprocessing, allowing for improved process performance by maintaining accurate and reliable flow measurement.

Economical & Reusable

The em-tec BioProTT Transducer works in conjunction with the em-tec non-invasive sensors, allowing for flow measurement without the need to replace a single-use sensor.

Overview

The BioProTT flow measurement system consists of a flow sensor, the Clamp-On Transducer, and an electronic evaluation system, the flow meter. Our system is available in different variants with standard interfaces (4-20 mA / RS-232), which allow an optimal integration into automated environments.

BioProTT Clamp-On Transducers attach easily to the outside of flexible tubing, thereby eliminating the need for splicing the lines or interrupting the process. They neither make contact with the fluid, nor induce shear stress on cells, nor do they cause a pressure drop in the system. Transducers can be removed easily at the end of the process with minimal cleaning and disinfection required. There is no calibration needed prior to each use. Our economical flow measurement system can be used for years without the operating costs associated with disposables - whether you use single-use components or reusable systems.

Features & Benefits

- Non-invasive, real time flow measurement

- Excellent accuracy, repeatability and stability

- Economical and reusable

- 4-20 mA or digital RS-232 output signals

- Remote zero input (BioProTT™ FlowTrack DINrail)

- Customer specific calibration for tubing, temperature and media

- User adjustable calibration enables field changes

- Clamp on and get started installation

- On site adjustment to calibration factor

Documents

Applications

- Single use systems

- Automated processes

- Processes utilizing flexible tubing

- Processes sensitive to shearing effects

- Processes requiring sterility in the lines

- As well as many other applications

Technical Specs

| Size (H x W x D) | 65 x 110 x 140 mm |

| Housing material Aluminum | Aluminum |

| IP-Code | IP 65 |

| Supply voltage | 24 V DC (± 10%) via power adapter or external supply |

| Power supply | Wall power supply with EU, UK, North America and IEC 60320 C8 connectors, others on request |

| Interface types | RS-232 / 4-20 mA analog: flow and received signal strength (RSS) |

| RS-232 cable | 9-pin D-Sub-socket (F) and USB adapter |

| Zeroing | Push button and digital interface |

| Adjustment and calibration | Adaptable with integrated calibration factor |

| Output Digital | [0.1 Hz, 1 Hz, 10 Hz] |